Damage during construction through moisture or fire leads to potential delays to contract, losses and expensive remediation works or even complete loss of a structure. A key advantage of light steel frame is its fire performance and protection from weather during the construction process.

MITIGATING RISKS

The amount of combustible materials in a light steel framed building is much lower, therefore the fire risk during construction and when in use is vastly reduced. Steel is non-combustible and does not add to the fire load of a building – reducing the fuel for a potential fire limits risk of damage and injury. This risk is further decreased by replacing some combustible materials with a concrete or screed deck on a steel frame rather than a timber deck.

Improving levels of occupants’ safety and increasing the quality of the build are under the microscope. Our research and perspective interviews with sector experts have equipped us with a deep understanding of the challenges faced by housing specifiers. Lack of performance testing is a major concern.

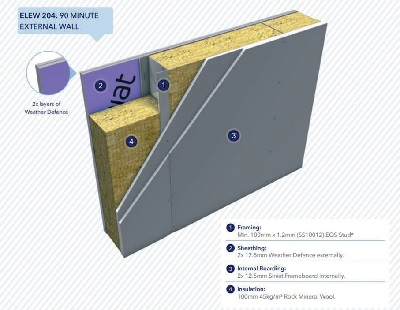

Developed in partnership with our Etex group partners, Siniat a leading expert in plasterboard and drylining systems and fire protection specialists Promat and FSi – our Thrubuild® complete load-bearing system range combines our technical and manufacturing expertise to deliver tested and certified solutions for light steel frame construction – all from one supplier.

This approach mitigates risk for housing developers because all components in our unitised walling and flooring system are rigorously tested together to verify compatibility and certify technical performance. Our Thrubuild® range provides a 30-year warranty – offering total confidence and peace of mind for residential specifiers.

To download our Thrubuild® Specification Guide go to: www.eosframing.co.uk/information-centre

Read our Full Residential Focused In the Frame Newsletter here