Wimbledon, the renowned All England Lawn Tennis & Croquet Club, commissioned a new open/close roofing solution for Court No1.

Situated alongside the existing roof apparatus on Centre Court, the system was required to minimise disruption and reduce the potential loss of income during inclement weather by providing protection for players and 26,500 spectators per year.

EOS designed two walls to envelope the entire circumference of Court No1. The inner wall was finished by the end of April 2017, the outer wall was to be constructed after the Championships in 2017. The project had a tight deadline, otherwise there would be a substantial loss of revenue in excess of £10million.

Key Data

Client:

Prater

Main Contractor:

Sir Robert McAlpine

Steel Framing System Supplier:

EOS

Materials / Type of System:

Pre-assembled Frames

DESIGN AND VISION

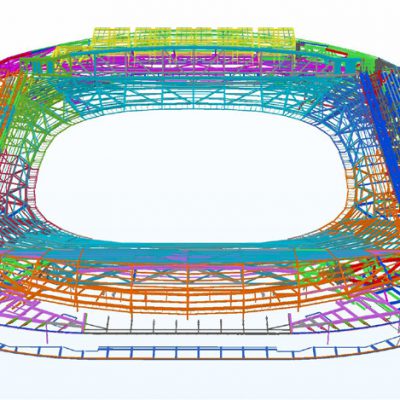

The EOS wall is integral to hiding the new structural elements on the scheme, to be left unfinished during the Championships. EOS delivered a fully inclusive service of design, supply and scheduling. The design included a range of features such as; bespoke and highly resilient wind posts, bracketry stiffened with bespoke elements and tall cantilevered solutions. The design was produced using a full BIM Level 2 modelling and design package with all manufacture data being taken from the BIM model. The scope of supply included all ancillary parts and fixings.

CONSTRUCTION

In order to achieve the best results, EOS has a dedicated in-house estimating team who worked to ensure Prater’s explicit requirements were met, taking into account the locality and site specifics. The ‘lump sum’ package approach offered by EOS meant that Prater and ultimately, Sir Robert McAlpine, had cost certainty throughout the scheme. By utilising BIM design and modelling, manufacture and delivery slots were known and pre-programmed weeks in advance. EOS provided dedicated on-site technical assistance to support preliminary toolbox talks as well as quality assurance checks during the installation. The product benefits from internal ISO9001 quality checks.

EOS utilised cold formed steel sections in a highly unusual manner, designed to mask the support structure for the new roof mechanisms, creating a variable radius curved wall to be used as a support and screening structure.

EOS provided lightweight cold formed C Section Studs, reducing the load on the foundations and supporting elements. The sections were cut to length with compound sections pre-assembled in the EOS factory where applicable, reducing installation times. All elements were bundled and issued to site colour coded and with parts individually labelled to match the design drawings to enable quick and easy location by site teams.

POSITIVE OUTCOMES

EOS took a linear product and formed something highly irregular, whilst remaining simplistic in nature. They applied a lightweight, efficient solution to create an integral masking screen to maximise the audience’s experience in a globally recognised setting, whilst virtually eliminating any sign of industrial support infrastructure. EOS utilised bespoke framing support that was introduced subtly and hidden behind the screens, continuing the seamless flow. The curving wall fits well within the circular nature of the existing stadium. The architectural lines flow consistently throughout and do not draw on the attention of the crowd or tennis players.

With EOS supplying all ancillary parts and providing cold formed studs/tracks cut to length, the tight deadline was achieved. Site issues were non-existent due to the design being BIM modelled and being manufactured in factory controlled conditions with stringent quality checks.